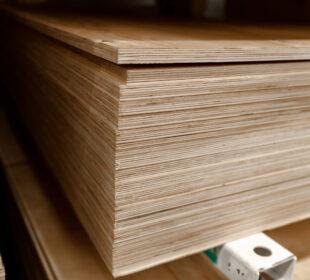

Malaysia’s plywood export prices to key Japan market have firmed up due to tight supply of logs for manufacturing activities and shortage of containers to ship the product.

Sarawak-based Shin Yang Group, Malaysia’s largest plywood supplier, has raised its export prices twice, once in December 2020 and another last month, according to the Japan Lumber Reports (JLR).

However, there was no mention as to how much were the increases in Shin Yang’s export prices.

Japan significantly raised its plywood imports from Malaysia to 62,400 cubic meters (cu m) in October 2020, up 20,200 cu m or 47.5% from the previous month, data from Japan Finance Ministry.

The October imports was the highest monthly since June (2020), bringing total imports from Malaysia to 599,100 cu m in the first 10 months of 2020.

Shin Yang, one of the largest timber companies in Sarawak, currently undertakes plywood manufacturing activities in three mills in Miri and Bintulu in the northern region.

StarBiz learnt that the group ceased plywood production in another mill about six months ago and switched to produce veneer due to the prolonged depressed plywood prices in the Japanese market.

This has reduced the group’s plywood production output.

“Malaysian and Indonesian plywood export prices are firm. There was expectation that the volume of imported plywood (in Japan) would increase in January (2021) but the manufacturing mills suffer log shortage and container shortage, so the supply has not increased, ” said JLR in its latest publication.

The trade journal, which is published every two weeks, has its contents reproduced by the International Tropical Timber Organisation (ITTO) Tropical Timber Market Report.

The JLR said the Japanese plywood importers are not able to place large orders with high prices when the demand for the product in the domestic market is stagnant.

It said port inventories of plywood seems to stay on tight through the current quarter.

Tropical plywood supply in the Japanese market is expected to drop as Daishin Plywood Industry Co – Japanese largest tropical plywood manufacturer – will cease operation and goes into liquidation next month (March 2021).

Daishin has for decades been processing imported tropical logs into plywood for walls and other applications.

In its report, the ITTO quoted Malaysian Panel Products Manufacturers’ Association chairman Sheikh Othman Rahman as saying that the plywood industry is currently facing a raw material shortage.

He said there is an acute shortage of raw materials in Peninsula Malaysia and that plywood and panel manufacturers are facing competition from sawmillers for logs.

Sheikh Othman suggests that a longer term solution to the log shortage is to export alternative raw materials, such as oil palm trunk, coconut trunk and rubberwood, and to venture into tree plantations.

The JLR said Japanese plywood mills are now less dependent on tropical logs as they have switched to use veneer in their plywood production. So, there is very little concern to log producing situation (in tropical countries).

The Japanese importers switched to Papua New Guinea (PNG) to source for their major supply of tropical logs when Sabah imposed a total ban on logs exports more than two years ago while Sarawak has significantly reduced its logs exports due to drastic cut in yearly production.