The Timber Trade Federation has announced new Guidance for members on sales of Marine Plywood in the UK.

Following a meeting of the Governing Board of the TTF on March 16th 2016, it was confirmed that: “As of June 1st 2016, all sales in the UK by TTF Members of non-independent third party Quality Assured Marine Plywood will cease.”

The decision has been ratified by the Governing Board and will form part of the new TTF Code of Conduct for panel product traders as this is updated. This means that only those products supported by Independent Third Party Quality Assurance can be sold as “Marine Plywood”.

The TTF will be issuing guidance via Merchants and other professional bodies as well as to its own members.

David Hopkins, Managing Director of the TTF said: “It is essential that our Members maintain the highest standards across all product ranges. We need to provide the market with the assurance and evidence it requires, that products sold by TTF members are fit for purpose and appropriate for the buyers needs.”

Given this potentially significant implication for TTF Members the matter was referred for consideration and confirmation by the Governing Board of the TTF.

About Marine Plywood

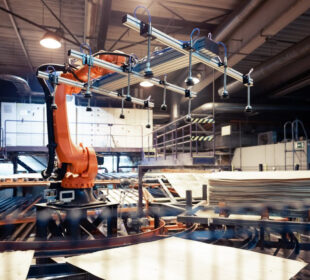

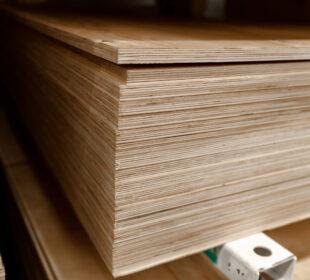

Marine plywood is manufactured from durable face and core veneers, with few defects so it performs longer in both humid and wet conditions and resists delaminating and fungal attack. Its construction is such that it can be used in environments where it is exposed to moisture for long periods. More recently, tropical producers have become dominant in the marine plywood market.

Okoumé from Gabon is now the accepted standard for marine plywood, even though the wood is not very resistant to rot and decay. Each wood veneer will be from tropical hardwoods, have negligible core gap, limiting the chance of trapping water in the plywood and hence providing a solid and stable glue bond. It uses an exterior Water and Boil Proof (WBP) glue similar to most exterior plywoods.

[gravityform id="1" title="true" description="true"]

[gravityform id="2" title="true" description="true"]