SmartPly Europe Ltd will invest €59 million in upgrading its production site at the UK Waterford location. Also, the Irish OSB manufacturer will invest part of this money to upgrade its production facilities with sustainable OSB solutions, such as new sizes and thicknesses according to the European market demand.

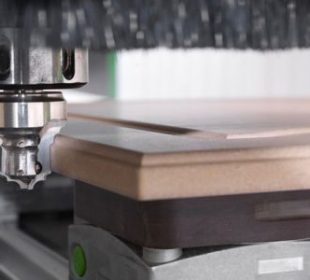

As WBPI online reported, part of this process will see SmartPly replace its multi daylight press with a new up-to-date continuous production line. Moreover, the company will invest in tenoning equipment, supplied by Schwabedissen to replace an existing American production line, as to process the OSB panels to tongue-and-groove panels.

The high quality of the t&g profiles will be acquired through the new double end tenoners, which will be upgraded with 4 processing motors per each side. Also, this new machine combination will have 40 servo motors to serve the automatic positioning of all tool positions, with the help of the latest Siemens S7 PLC technology, including Intouch Wonderware operator surface.

The machinery is aimed to be up and running this year and the order from SmartPly forms part of five bigger orders for double-end-tenoner combinations to be supplied in 2016 by Schwabedissen, as WBPI online reported.

The Schwabedissen machines are produced at the company’s facility in Hertford, Germany and its production is made in a 9000 m2 production hall. Other machinery concepts as the one to be built for SmartPly have already been implemented last year, for machines in Russia and Poland.

[gravityform id="1" title="true" description="true"]

[gravityform id="2" title="true" description="true"]